Types of Injection Molds

The most popular method used for the production of plastic parts is injection molding, a process that produces high quality, dimensionally accurate, and high tolerance plastic parts at a reasonable cost. Regardless of the type of injection molding, all types involve the use of molding machines, melted plastic polymers, and tooled molds that have cavities with the shape and configuration of a designed plastic part. Abtec Inc. is known worldwide for its ability to produce high quality plastic parts using the latest injection mold methods.

The categorization of injection molds is divided into three basic types, which are the mold feed systems, number of parts produced per cycle, and the number of mold cavities. All forms of injection molds have basic components for the shaping and forming of Abtec’s high quality plastic parts. Runners, guide pins, mold cavities, shots, clamping plates, and ejector pins are basic components of all forms of injection molding. How Abtec injection molds are implemented vary in accordance with the design of plastic parts.

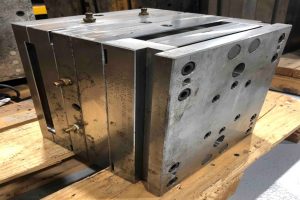

Full Chase Tools

Full Chase Tools are a type of injection mold that is designed for high-volume production. They consist of a mold base and a set of interchangeable inserts, allowing Abtec, Inc. to produce multiple parts with the same tooling. This makes them a cost-effective option for large-scale manufacturing as it reduces tooling costs and minimizes downtime during production.

Master Unit Die

The Master Unit Die (MUD) is another popular type of injection mold that is designed for small to medium-sized production runs. It consists of a unit die that houses multiple cavities, allowing manufacturers to produce multiple parts simultaneously. This type of mold is particularly useful for producing complex parts, as it can accommodate a variety of geometries and sizes.

Advantages of Master Unit Die

- Efficient production: MUDs allow for the simultaneous production of multiple parts, reducing cycle time and increasing overall efficiency.

- Versatility: Master Unit Dies can accommodate a wide range of part geometries and sizes, making them suitable for a variety of applications.

- Reduced tooling costs: MUDs are a cost-effective solution for small to medium production runs, as they require less tooling investment compared to other types of injection molds.

Plastic Injection Mold Design

A crucial aspect of the injection molding process is the design of the mold itself. The plastic injection mold design plays a significant role in determining the quality and functionality of the final molded part. Factors to consider during the design process include the type of plastic material, the desired part geometry, and the requirements of the production process.

Hot Runner Systems

One important consideration in plastic injection mold design is the use of hot runner systems. These systems consist of heated channels that guide the molten plastic from the injection unit to the cavities within the mold. Hot runner systems offer several advantages, including reduced cycle time, improved part quality, and reduced waste.

Modular Unit Die

Another option for injection mold design is the Modular Unit Die (MUD), which is similar to the Master Unit Die but offers greater flexibility in terms of mold configuration. Modular Unit Dies consist of interchangeable components and quick change, to reduce set-up and run times. Making this system an ideal choice for versatility in the production process.

Feed Systems

The feed or runner system is the set of channels that directs the molten plastic into the mold cavity. The types of feed systems are differentiated in regard to the temperature of the runners, which can vary from hot to cold and include insulated runners.

Hot Feed Systems

The runners for hot feed systems are heated and able to deliver molten plastic to multiple mold cavities. The heating of the system keeps the plastic molten from when it leaves the molding machine nozzle until it enters the mold cavity. Hot feed systems from Abtec are able to deliver molten plastic directly into the mold cavity without the use of sprues.

Hot feed systems produce plastic parts without imperfections, a factor that significantly reduces waste. They are widely used for high volume production with molds that have multiple cavities or full chase tools. The advantages of hot feed systems from Abtec are increased efficiency, excellent part quality, greater design flexibility, and lower energy costs.

Cold Feed Systems

Cold runner feed systems have unheated cold channels through which the molten plastic is injected into the mold cavity. Molds for cold feed systems have two or three plates. Runners for cold feed systems remain attached when a part is ejected. Three plate cold runner systems have a stripper plate that removes runners at part ejection. Although cold feed systems can accommodate a variety of thermoplastics and allow for other positive features, they produce a great deal of waste and parts with lower tolerances.

Insulated Feed Systems

Insulated feed systems are a combination of cold and hot feed systems. They have runners that are similar to cold feed systems but apply heat to the runners using various heating methods. The heaters for insulated systems form insulated culls that create the effects of hot feed systems. As with heated runner systems, the heat from insulated systems helps molten plastic maintain its temperature as it enters the mold cavity.

Mold Design

Mold design determines the number of molded parts created. The three types of mold designs are single, multiple, and family. The development of molds for injection molding is a crucial part of the manufacturing process. At Abtec, our team of designers works with our clients to develop molds that perfectly fit a customer’s requirements. The properly tooled molds from Abtec produce accurate shapes and form plastic high tolerance parts with exceptional precision.

Single Cavity Molds

Single cavity molds produce one part per injection cycle. They are the slowest of the mold designs but are affordable to produce and are a perfect option for short production runs.

The simplicity of single cavity molds allows for greater control of the injection molding process. In some cases, single cavity molds are used in groups in order to keep production rolling even when one of the molds fails.

Multiple Cavity Molds

Multiple cavity molds are one of the most common types of injection molds used at Abtec and are able to produce multiple identical parts in a single cycle. Unlike single cavity molds, the tooling of multiple cavity molds is expensive and requires time to produce. Multiple cavity molds are designed for high volume production. Their wide use is due to their ability to increase production speed and lower per unit costs.

Family Molds

Family molds are like multiple cavity molds in that they have multiple mold cavities. What differentiates family molds from multiple cavity molds is their ability to produce several different parts in one cycle instead of the same parts. The tooling of family molds is expensive due to the creation of several dissimilar cavities in a single mold. Regardless of this drawback, family molds reduce production and operating costs as will as save time in regard to product assembly and production.

Mold Plate Type

A third factor that is used to classify injection molds is plate types, which include two plate, three plate, and stack mold types. The plates of an injection mold form the mold cavity. They influence the cost of the mold, the finish of mold parts, and the efficiency of the production process. Plate types vary from their simplest form, which is two plate molds, up to more complex and intricate designs, which is stacked plate molds.

Two Plate Molds

Two plate molds are the most common form of injection molds. They have low tooling costs and are single cavity molds. The design of single plate molds includes a parting line where the core and plates come together. For single plate molds to produce high quality parts, their gates, runners, and parting lines must be perfectly aligned. Two plate molds are used with any type of runner system and have low tooling costs.

Three Plate Molds

Three plate molds have a third plate referred to as the stripper plate, which removes the runner system when the cavity and core plates separate. The design makes production faster since there is no need for manual separation or recycling of the runner system. The downside of the design is increased tooling costs, which is necessary to ensure the precision of the cutting mechanism of the third plate. The use of three plate molds is for cold runner systems since hot runner systems do not require the removal of runners.

Stack Molds

Stack molds have a unique design that includes two, three, or four levels of plates for increased efficiency. In addition, the configuration of stacked molds requires less clamping. As with other multiple types of molds, stack molds have high upfront costs due to their requirement of extra tooling. The lower clamping tonnage makes up for the increased tooling costs by reducing operating costs.

Unscrewing Molds

A feature of injection molds that is necessary for the production of bottle caps, nuts, bolts, and auto parts is threaded molds. Screw or bolt types of products cannot be produced using the traditional knock off method due to their draft angle. Unscrewing molds help complete the manufacturing process by removing molded screw parts without damaging their threads.

Choose Abtec, Inc. for All Your Injection Mold Design Needs

Choosing the right type of injection mold is essential for achieving efficient and cost-effective production of high-quality plastic parts. Whether you opt for Full Chase Tools, Master Unit Die, or another mold design, it’s important to consider factors such as cycle time, tooling costs, and production requirements to ensure the best possible results.

At Abtec Inc, we have extensive experience with various types of injection molds, including hot runner molds, cold runner molds, and multi-cavity molds. To learn more about our expertise and how we can help with your manufacturing needs, contact us or visit our custom plastic injection molding page for more information. For answers to frequently asked questions, check out our FAQs section.