Advanced technology gives companies more options when it comes to producing plastic components. Plastic injection molding and 3D printing are two of those options, and they both have their advantages, depending upon the application. While 3D printing is relatively new and attention-grabbing, plastic injection molding is still a trusted solution for precision manufacturing.

3D Printing vs. Plastic Injection Molding

3D Printing vs. Plastic Injection Molding

It helps to understand the difference between these processes:

- 3D Printing: As an additive manufacturing process, layers of material are put together to create the final shape as designed in a digital file.

- Injection Molding: A proven process for 150 years and counting, injection molding starts with the creation of a mold. The materials are melted, then injected into the mold where it’s left to cool and harden into the finished product.

When determining which process is right for your product, you need to consider the pros and cons of each. 3D printing is great for small production runs and prototyping of small parts or components. Because there’s no mold that has to be created, it’s easy to make changes to the digital design—giving you lots of flexibility when perfecting a new product or when producing something you know you will make changes to on an ongoing basis.

As a newer technology, there are occasional glitches to the process that can interrupt production. 3D printing is also more likely to leave ridges and small defects in the product and 3D printing tolerances are not tight, so you may not end up with precise replicas if you’re creating multiple units.

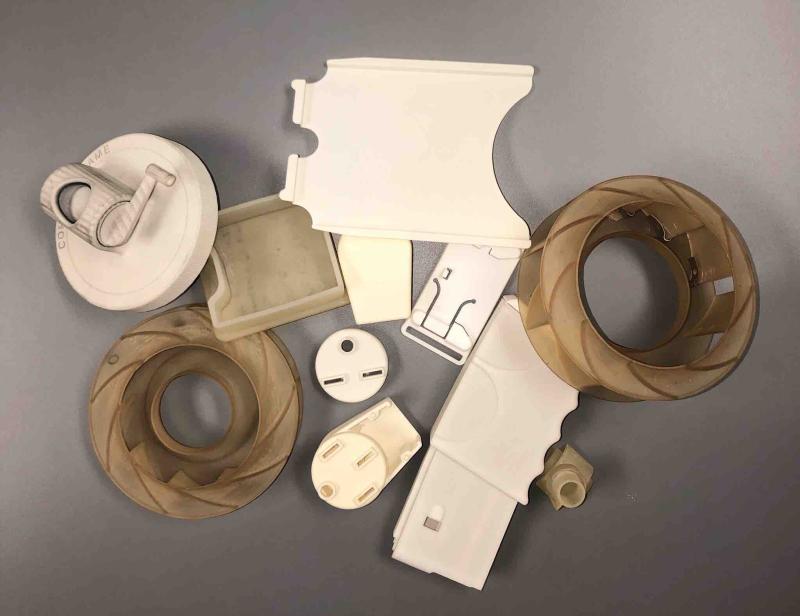

Plastic injection molding is ideal for larger production runs of all types of components—big or small, simple or complex. After the mold is created, you can work quickly to produce hundreds or thousands of high-quality components with consistent precision. The bigger the run, the lower the cost per unit.

Once built, it can be costly to make changes to the mold. Which is why it is important to perfect the design before tooling begins. This is where 3D printing and custom injection molding work well together: 3D printing can be used for experimenting and prototyping, then you can ramp up production with injection molding.

Chances are, you use products every day that are made with 3D printing and injection molding:

3D Printing Applications

- Clear braces

- Hearing aids

- Football helmet liners

- Bicycle frames

- Razor handles

- Jewelry

- Mascara brushes

- Shoe insoles

- Biodegradable pens

- Eyeglass frames

- Unique shower heads

- Custom car accessories

- And more

Injection Molding Applications

- Mop heads

- Equipment housings

- Vending machine components

- Medication trays

- Insulators

- Roofing vents

- Raised flooring panels

- Deck fasteners

- Bird feeders

- Toilet seats

- Barbecue grill accessories

- Serving pans

- Children’s furniture

- Collectible models

- Point-of-purchase display racks

- Flower pots

- And more

Choose Custom Injection Molding with Abtec, Inc.

With about 100 years of combined experience, Abtec, Inc. offers custom injection molding and a variety of secondary operations and support tooling to our clients in the pharmaceutical, food and beverage, aerospace and defense, telecommunications, and medical industries, among others. We specialize in innovative solutions for even the most complex designs.

High-quality injection molding starts with a great mold design, and our engineers can help with that, along with material selection and tooling recommendations, to ensure you get the components you need. With state-of-the art technology and a dedicated team of experts, Abtec is a trusted plastics partner around the globe.

Both 3D printing and plastic injection molding have their place in manufacturing, and there are many opportunities for these technologies to work together for the benefit of the client. For high-volume runs of small or large components, injection molding has the advantage of being efficient and cost-effective and offering precise replications of the product. Take a look at our blog to learn more about custom injection molding and how we can help with your next project, then contact us to get started.