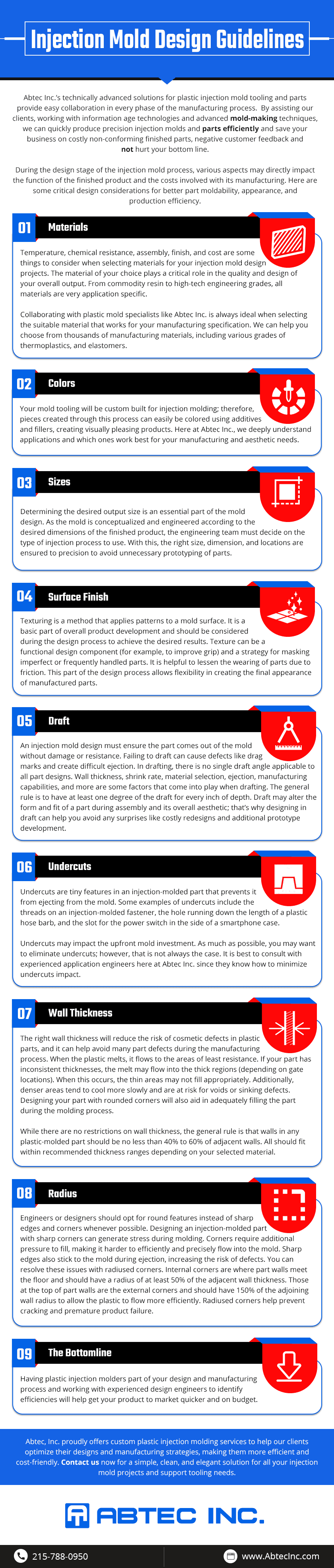

Abtec – New Custom Injection Mold Tool Building

The process of plastic injection molding necessitates sourcing and acquiring mold parts, tools, and equipment to meet the needs and requirements of a part or component. The process for accumulating these components is referred to as tool building or tooling, an aspect of injection molding that is essential to the success and quality of finished parts. Abtec’s team of professionals have the experience, skills, and abilities as mold builders to engineer the highest quality components and parts for new custom injection mold tool building.

As an addition to Abtec’s state-of-the-art manufacturing facility, we have the added technologically advanced new tool building features that allow our staff of experts to efficiently and quickly put together tools to produce high quality parts. This aspect of plastic injection impacts the price, quality, and turnaround times of custom-made parts. We at Abtec are well aware of the requirements of our industrial partners and work daily to provide the type of service the meets their needs.

Continue reading “New Custom Injection Mold Tool Building”