At Abtec, Inc., we specialize in custom injection molding, creating tools and parts for customers all over the world from prototype to large production runs. Plastic injection molding is a manufacturing process that involves injecting liquified plastic into a mold, allowing it to conform to the shape of the mold and harden to create a specific shape. This beneficial process has numerous applications in many industries, including the medical industry.

Components and devices for the medical industry must comply with strict industry standards and be made from durable, reliable, and FDA-approved materials. Plastic injection molding not only meets these criteria, but it also offers a host of additional benefits for the medical industry.

The Standards Met & Materials Commonly Used

Parts made for the medical industry must conform to strict standards due to the nature of their use. The FDA outlines different requirements for implantable devices and those being used for medical instruments, and other external use; therefore, it is crucial to consider your application when selecting a medical-grade plastic for the molding process. Other factors such as strength, resistance to heat and chemicals, and operating environment must also be considered when selecting a material to ensure that the part will hold up while in use.

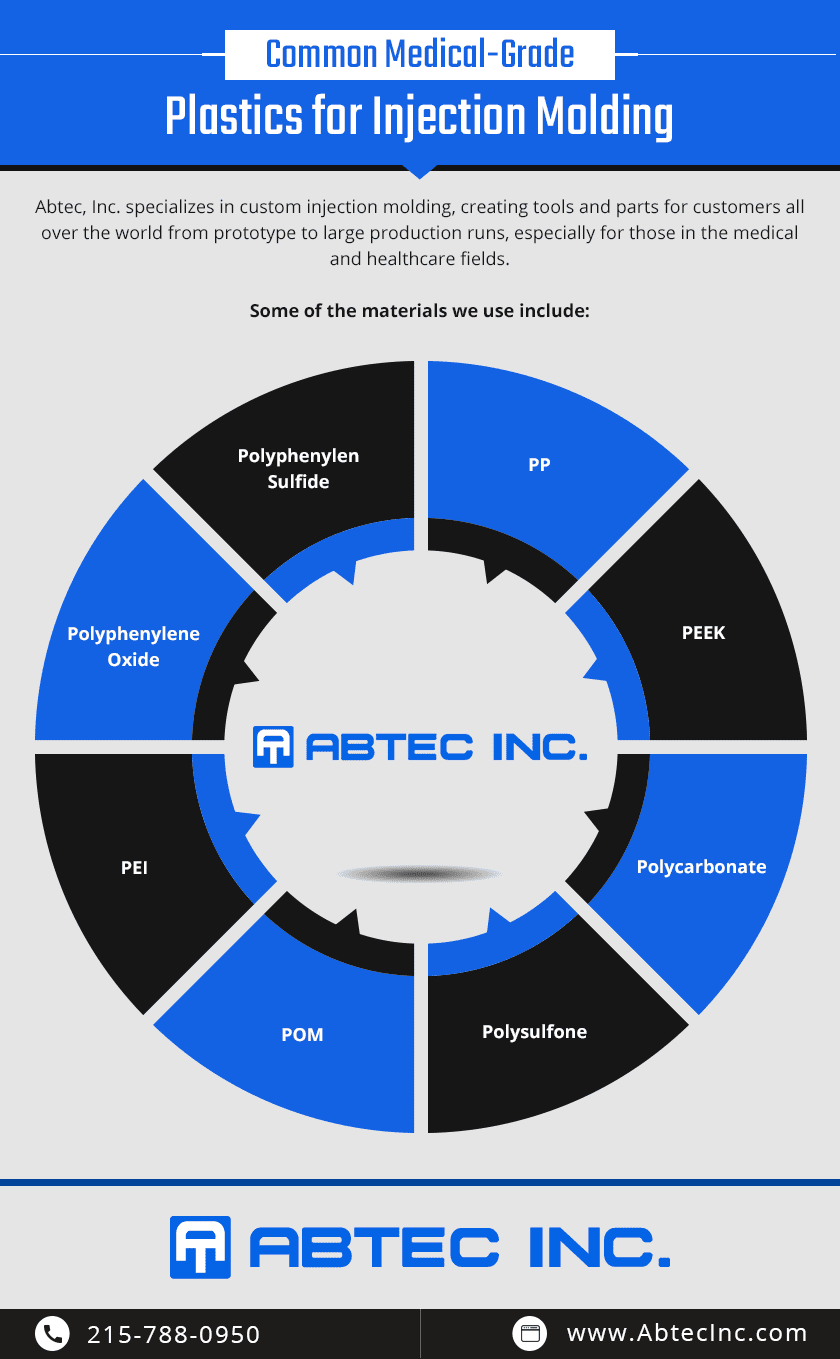

Common medical-grade plastics that can be used with injection molding include:

Common medical-grade plastics that can be used with injection molding include:

- PP. Heat and radiation resistance over extended periods

- PEEK. Resistant to chemicals and high temperatures, resists fatigue and cracking, works well in radiation-prone environments, and easily sterilized.

- Polycarbonate. Flexible, high heat resistance, transparent, UV resistance, durable, and resistant to flames.

- Polysulfone. High temperature with high mechanical strength and rigidity. Good creep strength that is remarkably high over a wide range of temperatures.

- POM. Resistant to multiple cleaning and disinfection agents, and to a number of solvents. It can be steam sterilized by medical industry’s usual methods, and will maintain good strength, stiffness, and dimensional stability.

- PEI. Remarkably high creep resistance over a wide temperature and a high permanent operating temperature. Resistance to hydrolysis, along with dimensional stability

- Polyphenylene Oxide. Strong with outstanding mechanical, thermal and electrical properties. Very low moisture absorption, low thermal expansion, excellent insulating properties, flame resistance, and dimensional stability over a wide range of service temperatures.

- Polyphenylen Sulfide. A semi crystalline, high temperature thermoplastic polymer. Chemically resistant polymer with amazing mechanical strength, even at temperatures above 200°C (392°F), very stable dimensionally with low susceptibility to creep.

There are many benefits to injection molding for the medical industry, the most prominent being how easily and quickly supplies can be made. Unlike other materials, plastic can be easily injected into a mold to take almost any shape needed, curing into a durable piece of equipment with high levels of precision. This helps to keep prices low, allowing medical facilities to remain sufficiently stocked with important instruments without excessive costs. Cleanliness is also a benefit, as many of these plastics are easy to clean and sterilize without issue.

Abtec Provides Medical Injection Molded Parts

The injection molding process follows these steps:

- Create a mold. Injection molding requires a pre-made mold for the material to be injected into. This can be a template for existing pieces or a custom design.

- Inject. Pelletized resin which is heated to liquid, is injected into the mold. The plastic fills in the spaces within the mold, forcing out air through tiny vents along the sides.

- Cooling. The melted plastic is cooled, allowing it to harden. This is done with a network of water pumps or air vents built throughout the mold that displace the heat from the plastic.

- Remove and clean. Once hardened, the part is removed/ejected from the mold and the part is (if necessary) cleaned of any debris or bits of unnecessary plastic.

Abtec, Inc. is at the forefront of medical injection molding and can produce parts or fittings for a large number of applications. We’ve worked closely with our customers to manufacture top-of-the-line moldings and products, including:

- Ventilators for use during the COVID-19 pandemic

- Parts for radiological cancer treatment

- Catheter locks

- Medical Equipment Housings

- & and, a plethora of parts for a variety of medical devices

Additionally, our on-site cleanroom facilities are frequently in use to eliminate contaminants from parts that are designed for use in laboratory and research facilities.

Medical Plastic Injection Molding from Abtec, Inc.

Plastic injection molding is an invaluable manufacturing technique for the medical industry and beyond. This process allows many parts to be created from medical-grade plastics in a fraction of the time it would take to do so by hand or with other methods. With numerous options for plastic types and applications, medical injection molding continues to be an integral part of industry.

To learn more about our plastic injection molding services for the medical industry, contact us today. You can also email any questions directly to us at sales@abtecinc.com.